In the past few months, a new material has come into light – aerographite.

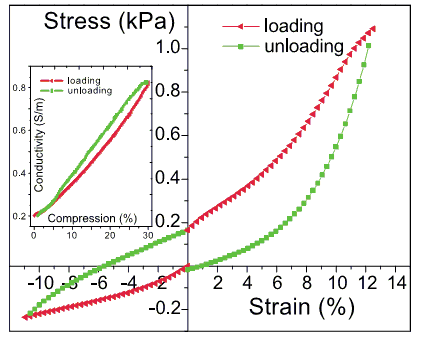

It has several remarkable properties. The most noteworthy is its low density. It has the lowest density of any material ever created including air. The density is 0.2mg/cm3. In addition, it can be compressed three orders of magnitude and then spring back to its original size. It is also electrically conductive and conductivity can be modified by compressing the material. [1]

The structure is an interconnected network of closed shelled microtubes. The walls of these tubes are approximately 15 nanometers thick but have a tube diameter in the order of a micron or more. Unlike multiwalled carbon nanotubes, the microtubes show less curvature. The tube surface can be modified by growth conditions to introduce wrinkles that increase mechanical stability.

It is processed from ZnO powder that is heated to 900°C. This transforms the ZnO to a three dimensional network of nanocrystals and microcrystals. This is then placed into a chemical vapor deposition reactor where carbon and hydrogen rich gas sources are introduced at a chamber temperature of 760°C. Aerographite can currently be fabricated up to a volume of several cubic centimeters.

Other interesting properties include:

- high optical absorption. It appears black

- flexible and compressible.

- hydophobic so will wet well to epoxies.

- high temperature stability

- chemically resistant

Some potential applications include:

- Electronics for aerospace applications. The low density property means low acceleration forces which is ideal for high impact and high vibration environments.

- Electrode for Li ion batteries. Mechanical robustness, high surface area and low specific weight are all beneficial properties for this application.

Reference:

[1] http://onlinelibrary.wiley.com/doi/10.1002/adma.201200491/pdf